Anomaly Detection with Computer Vision and Industrial Applications

This article comprehensively explains the importance, application areas, historical development, and technical approaches of computer-vision-based AI anomaly detection in industrial production lines, highlighting its advantages in time, cost, and reliability for quality control processes.

What Is an Anomaly?

In general, an anomaly refers to situations where something is observed to deviate from what is expected. Although anomalies may be interesting in many contexts, in environments where production and quality must be high, they result in cost and customer dissatisfaction. In today’s world, with increasing demand, industrial automation has become even more important to meet this demand. In this context, inspecting products obtained along or at the end of the production line at the same speed, preventing defective products from causing cost losses, and ensuring customer satisfaction and continuity have made anomaly detection systems increasingly important. In quality control processes carried out by humans, defective products may still leave the line due to human-related factors such as fatigue and lack of attention. Especially in industries operating with shift systems, shift changes may cause a decrease in quality control performance during these intervals. For this reason, AI-supported solutions that can operate 24/7 with consistent performance ensure stability in these processes. With the increase in computational power of artificial intelligence, processes that were previously attempted using sensors are now carried out using AI-supported industrial cameras powered by computer vision.

Computer-vision-based AI systems enable damage to be detected as early as possible or at least before leaving the production line, ensuring that both production-stage and post-production time and costs are optimized. For example, while the logistics of a defective product already incur a cost, if this defective product is noticed in the field and returned, it requires the extra part to be retrieved and re-enter the logistics process.

Application Areas of Anomaly Detection

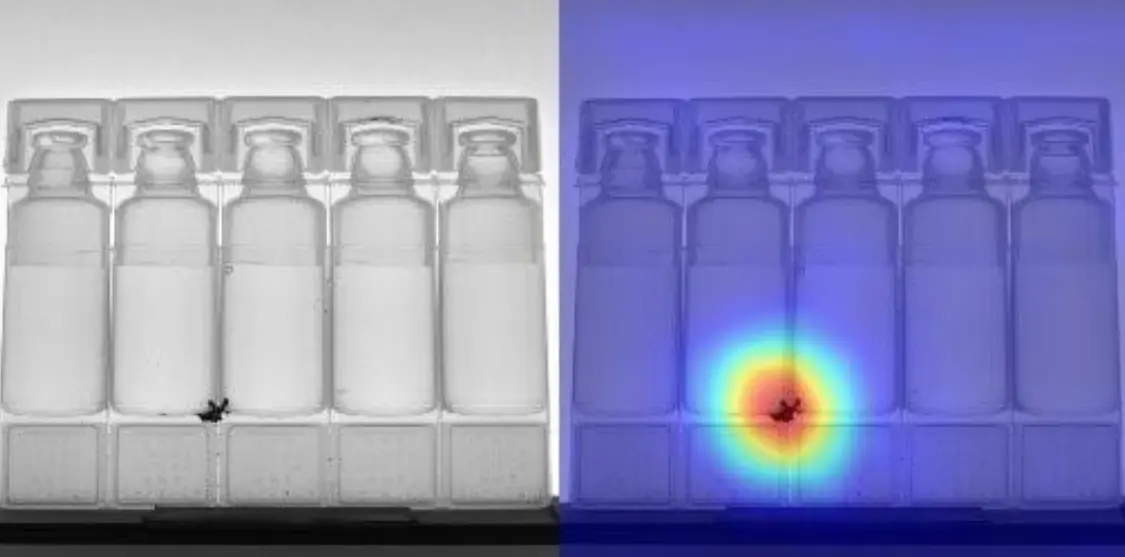

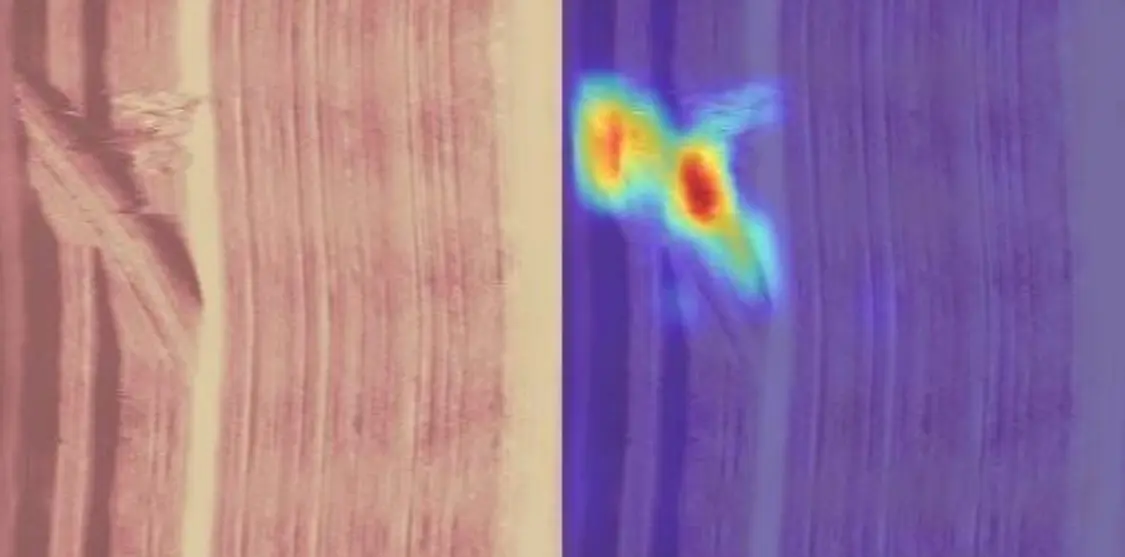

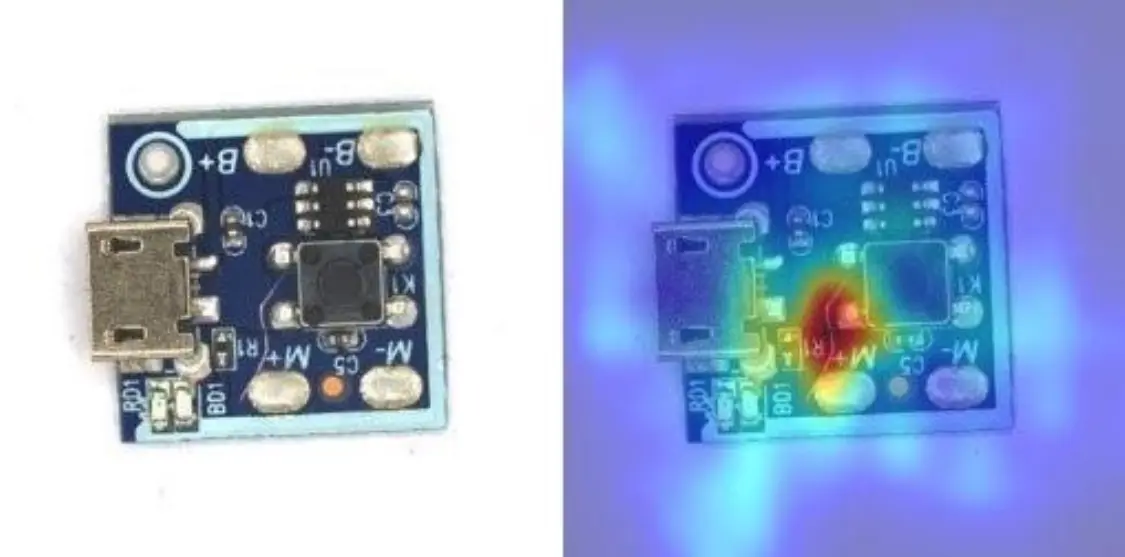

Anomaly detection with computer vision can be applied in manufacturing, healthcare and pharmaceutical production, food quality and packaging, chip manufacturing, and any field where conveyor-based production is performed. The examples can be further increased. It can be used for surface inspections of fast-moving parts on conveyors, presence-absence checks, and missing part inspections. In general, labeled data are used to train AI models such as object detection models. In such cases, all situations to be detected can be predicted and foreseen in advance. However, in anomaly detection scenarios, it is very difficult to claim that the number of possible anomalies that may occur in each product is predictable and limited, and to detect all of them. Therefore, instead of detecting errors directly, anomaly detection can be performed using methods that learn how a correct product should look and measure how different the inspected product is from what it should be. Technically, this method is called unsupervised learning.

Food Packaging

Pharmaceutical Manufacturing

Surface Inspection (Wood)

Electronic Component

Today, as the importance of artificial intelligence increases, approximately 30% of global anomaly detection solutions in production lines are actively based on computer vision.

A Brief History of the Development of Computer Vision Methods

Although artificial intelligence may seem like a newly emerging field due to daily news and developments, its journey began in the 1950s when Alan Turing, considered the father of computer science, sought an answer to the question “Can Machines Think?”. Even the famous Turkish mathematician Cahit Arf wrote an article on this topic. Since then, artificial intelligence has always been an actively studied field. It gained momentum during periods when computer processing capacity increased, and in 1989, French computer scientist Yann LeCun and other researchers developed an application that could recognize and classify handwritten postal codes from images. From that time onward, the field of computer vision continued to develop through various competitions on widely accepted datasets, especially for classification tasks. In 2012, Geoffrey Hinton and other researchers achieved remarkable success on the ImageNet dataset consisting of 1000 different classes by using deeper neural networks with increased computational power, which once again encouraged researchers to focus on this field. The increase in computational power achieved using NVIDIA GPUs in the 2010s and today has enabled solutions even for challenging problems such as understanding and generating natural language. As a result, computer vision methods such as object detection and segmentation, which allow analytical processing on images, have further developed and diversified.

Computer Vision in Anomaly Detection

When computer vision is mentioned, methods such as image classification and object detection in images and videos usually come to mind first. In healthcare, anomaly detection for diseases using medical images and scans is also a common application. By using images obtained from high-resolution cameras in production lines, anomalies such as damage, missing parts, and deformations can be detected, preventing cost and time losses.

To make quality control processes more effective and to increase performance in production lines, computer-vision-based AI systems have been increasingly preferred with Industry 4.0. For anomaly detection solutions integrated into production lines to meet expectations, it is important to use the right components with the right software. While CCTV cameras are sufficient for campus security, higher-resolution cameras should be preferred in production lines. At the same time, such cameras are more suitable for operating for long periods at speeds that prevent frame shifts and under industrial working conditions and temperatures. Inference and decision-making are performed using the most suitable AI models on the images obtained from these cameras.

AI solutions can operate on cloud services or edge devices to produce results. This preference may vary according to the policies of companies that want to integrate anomaly detection into production lines. Considering whether the application should operate in real time or with delay, the most suitable methods can be selected in terms of performance and cost. Cloud services enable faster inference and decision-making on images obtained from the line using powerful servers, but they also require sending images over open networks, which is generally undesirable. Edge devices, on the other hand, are compact computers optimized for computational power and can be used internally within the company. These edge devices can generate signals for automation systems such as SCADA in large production lines. Therefore, high-performance and cost-effective edge devices are preferred. Since anomaly detection generally requires task-specific solutions, it must be customized for each customer.

#anomaly #HeatMap #ComputerVision #IndustrialApplications #ArtificialIntelligence #ProductionLine #QualityControl #UnsupervisedLearning #ImageProcessing #ObjectDetection #HistoryOfAI